Bettis

Bettis执行机构气缸

Bettis Valve Actuators | bettis actuators | bettis电动执行机构

Bettis世界气动拨插执行机构的领导者,在ESD,放空阀、切断阀应用比较

广泛。 Bettis成立于1929年,逐步发展成为阀门执行机构的制造集团公司

及先驱。今天,Bettis作为EMERSON公司的品牌,已成为世界范围内气动

、液压阀门执行结构生产制造的领先者,Bettis的执行机构可以应用于能

源工业的所有领域,包括油气传输,石油炼化等,同时还应用于化工、

电厂、核电、食品等行业。

Bettis的生产中心位于德克萨斯的沃勒,为了更好的为客户服务,

Bettis在世界各地设有销售服务机构。 Bettis可以提供线性,角行程等

执行机构,有弹簧复位和双作用结构,动力可以选用气动、液压、电动,

输出扭矩从5N?m到678000N?m,轴向力输出从890N到2001600N,行程长度

可达154cm。

Bettis Valve Actuators 拥有严格的质量管理体系,对产品生产的每个环

节都进行检测,所以可以保证每个产品在出厂前都进行了彻底的检测,我们

通过了ISO9001认证。

●CBA300型执行机构(CBA-300 Series Valve Actuators ):

1)气动或液动;

2)结构紧凑重量轻,适用于球阀、蝶阀、柱塞阀等90度角行程阀;

3)达到IEC60529规定的IP66和IP67M;

4)扭矩输出:

双作用型 达2520 N?m

弹簧复位型 达1296 N?m

5)标准操作压力 达1Mp;

6)工作温度-29℃到93℃

7)可选型号允许工作温度可达-40℃到177℃;

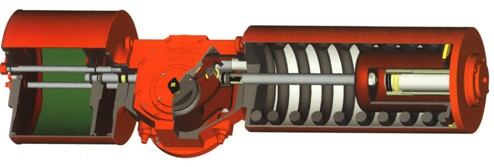

●G型执行机构(G-Series Valve Actuators )

1)气动或液动

2)适用于球阀、蝶阀、柱塞阀等90度角行程阀门;

3)磨损补偿功能,如轴杆、轴承、密封等;

4)工作情况下,弹簧强制锁定;

5)由于采用偏心轴结构,所以消除了开关、调节器密封、轴承的缺点;

6)结构紧凑,重心居中,较以前产品有了很大提高;

7)简单、易换的易损件;

8)对气候、动力空气有强抗腐蚀能力;

9)防护等级达到IP66或IP67M;

10)输出扭矩:

双作用 678000N?m;

弹簧复位: 339000 N?m;

11)操作压力:

气动 0.3~1.4Mp

液压 3.4~34.5Mp

12) 工作温度-29℃到93℃

可选型号允许工作温度可达-18℃到177℃

可选型号允许工作温度可达-46℃到82℃

Bettis was established in 1929 as an oilfield supply house and

manufacturers' representative. The company later evolved into

a manufacturing organization, becoming a pioneer in the valve

actuator business.

CBA-Series (Pneumatic Scotch Yoke)

CBA-300 Series (Pneumatic Scotch Yoke)

D-Series (Pneumatic Rack & Pinion)

HD-Series (Pneumatic & Hydraulic Scotch-Yoke)

G-Series (Pneumatic & Hydraulic Scotch-Yoke)

G系列执行机构,适合大扭矩

1、 模块化结构被广泛的应用在最新一带的电动执行机构-ELQ系

列,插入式模块可以很容易扩展整个控制功能,它可以使功能单

一的执行机构很容易的扩展成一个功能齐全的执行机构,并同时

具有传统的4-20mA模拟量信号和最新的数字通信功能。电动执

行机构配有方形驱动趁套,安装标准为ISO5211/DIN3337。另外

EL-O-MATIC也能提供其他的驱动趁套,如双D形轴套,键连接轴

套和特殊尺寸方形套,方便连接。

2、 标准:防水等级IP67(可选IP68),IEC529,NEMA4,

ICS6-110.15

防爆等级EEX d ⅡBT4,EN50014/EN50018,NEMA,9,

ICS6-110.24

安装标准:ISO5211/DIN3337

? 动力消耗低,节约成本

? 100%工作制,可以被应用在各种场合,并有防止电机过热功能

? 在整个行程中保持100%扭矩,可以被应用在各种场合,甚至应用

在具有复杂扭矩模型的阀门上

? 每小时可以启动3600次,可以应用在所有需要调节的管道领域

? 配有灵活的手动装置,可以随时保持手动控制

? 紧凑的结构优化设计,消除了阀门轴所受到的不均匀载荷,同

时还防止在管路上出现的应力,使整个结构保持在一个良好的平

衡状态中

? 模块化设计:他们使一些插入式模块,既可以在工厂预先组

装,又可以在分销商处或现场组合安装,不需要特殊的工具。

而且所有这些附件都可以安装在执行机构上,按客户要求可配

备或不配备机旁控制箱

|

|

Bettis products are used in almost every

energyrelated industry, including oil and

gas oduction - both onshore and offshore

- oil and gas trans-mission, petrochemical

and petroleum refining. Other markets

include chemical, power industry including

nuclear, pulp and paper, food and

beverage, pharmaceutical, textile and

water system.

|

Bettis' CBA-Series pneumatic actuators are compact, lightweight

and ideally suited for automating ball, butterfly

and nonlubricated plug valves, or any quarter

turn (90 degree) rotating mechanism. These

efficient, low maintenance actuators,

with optional controls, provide a reliable

method of operating and confirming valve

position for a fully automated process.

The CBA-Series, available in double-acting and

springreturn models, are independently certified

to BS 5490: 1977 - IP66 and IP67M for water

ingress protection. Doubleacting CBASeries

actuators, requiring pressure to rotate in

either direction, are available with

guaranteed minimum torque outputs

to 12,245 lb-in (1,384 Nm). |

|

The CBASeries springreturn models require

pressure in only one direction of travel

and are suitable for fail clockwise or

counterclockwise applications without

modification. These models produce gua

-ranteed spring ending torques to 4,971

lb-in (562 Nm). Standard construction

CBA-Series actuators are designed for

operating temperatures of -20°F to +200°

F (-30°C to +95°C). High temperature

trim allows continuous operation from 0°

F to +350°F (-18°to +177°).

Additionally, low temperature trim allows

operation from -40°F to +180°F (-40°C

to +82°). Consult factory when tempera-ture requirements exceed these limits.

Operating pressures for the CBA-Series

range from 40 up to 150 Psig (3 to 10 Barg).

Typical Applications:

Automation of ball, butterfly and plug

valves Automation of louvers and dampers

Automation of any quarter-turn mechanism

Key Features:

Outer LipType Torque Shaft Seals restrict

external contaminants, providing a high

level of corrosion and water resistance ORing

Sealed Cylinders essentially eliminate

the possibility of any cylinder leakage

throughout the full range of operating

and climatic conditions Standard Accessory

Mounting Pad is identical on all CBA and

CBA-300 Series models allowing the panel

mounting of controls

Piston Heel and Yoke

Pin Bearings man-ufactured from PTFE/bronze

help ensure smooth and consistent torque output

and increase total cycle life

Totally Enclosed Body

provides complete protection of all internal moving

parts and minimizes the chance of injury to

operating

personnel The ScotchYoke Mechanism transforms

linear movement of the piston into

a 90 degree rotating movement,

providing optimum start or end torque

Center Bar, made of high strength alloy

steel, guides the piston throughout

its full stroke, preventing metal to

metal contact with the cylinder bore

Bidirectional Travel Stops are an

integral part of the actuator all-owing 80° to 100° total travel

adjustment. Extended travel stops

are optional Critical Bearing Surfaces are

permanently lubricated with a baked

on dry film lubricant containing

unique corrosion inhibitors

XylanTM Cylinder Coating, the

standard internal coating on all CB-ASeries actuators. This

fluoropolymer coating is highly resistant to abras-ion,

thermal shock and provides excel-lent lubricity and low

friction proper-ties. Corrosive properties of salts and

other chemicals normally found in the

atmosphere or instrument air supply

system will not adversely affect its

performance. XylanTM bonds to the

chemically prepared surface of the

steel cylinder so effectively tha-t, unlike other coatings, cracking

and flaking are virtually eliminated

Dual Valve Mounting Interface allows

the flexibility to change the spring

fail mode, without disassembly of the

actuator, by simply inverting the act-uator. They may be installed in any po-sition; parallel or

at right angles to the flow line, in the vertical or the horizontal planeWellGuard? PWG Valve

Actuators

The WellGuard? piston range of pneuma-tic Control Fluid Powered linear actua-tors is designed to be used in conjunc-tion with Bettis valve bonnets to prov-ide open and close

control for major b-rands of API 6A through conduit reverse acting gate valves fitted to oil and

gas

wellheads and production flow lines.

These actuators can be used with API

6D and ANSI B16.34 valves where the

bonnets are built to Bettis design.

Key Features

Lightweight

Actuator Upper Shaft acts as visual

position indicator

Easy maintenance and disassembly, no

special tools required

Construction uses no large mounting

threads, eliminates galling and corrosion

Designed for interchangeability with Bettis

pneumatic diaphragm and hydraulic piston

WellGuard linear actuators Actuator temper

-ature operating range: –50°F to +150°

F (–58°C to 65°C)

Bonnet temperature class "L to U" and tes

-ted for 300°F Service

Suitable for use with eutectic (fusible)

lock open device

The company headquarters in Waller, Texas (near

Houston) houses more than 145,000 square feet

of covered manufacturing, research, engineering

and office facilities. Bettis also has an 88,000 sq-uare foot manufacturing facility in Canada

, avalve automation facility in France, and

a direct sales office in the United Kingdom.

Since Bettis Corporation's inception, it has

continuously expanded both its physical capacit-y and its product lines. Its growth has come, in

part, from the acquisition of some of the worl-d's most reputable actuator manufacturers wit-h a myriad of offerings and specialties. As a r-esult of these acquisitions, Bettis now operate-s plants worldwide coupled with a global sales

and distribution network unmatched in the indus-try.

|

|